Testing and Quality Control

We have an expectation that our products enhance the overall quality of our customers’ products. We invest a lot of time and resource into ensuring that our quality processes are going to deliver to the very highest standard of our customers’ requirements.

We inspect and test, where possible, 100% of all products that leave our facility. In fact some items are tested and checked up to 5 times throughout our production process.

Quality Is at the Heart of All We Do.

Quality for us starts with specifying the product and ensuring that we are fully understanding all requirements and compliance necessary. Our processes include providing drawings, and samples prior to production volumes being made. This sometimes takes a bit longer, but it captures a lot of issues that otherwise would be picked up in the first couple of production runs. So many of our customers express frustration with our competitors that it takes multiple orders to get things right. At Fero, we strive to ensure that our first order is right every time.

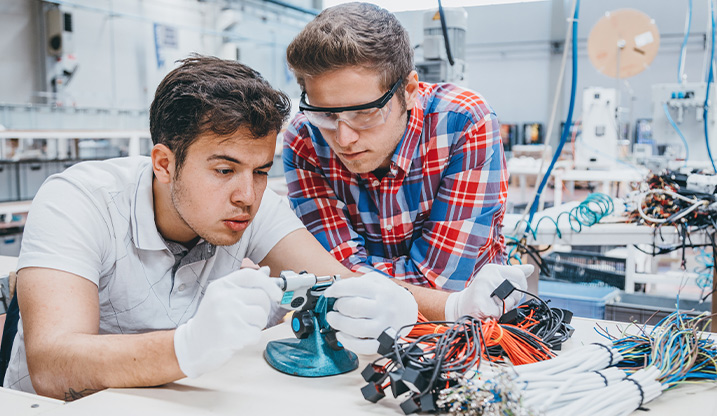

Wire Harness Quality

Of course the form and fit of a loom is critical, and we are using a number of techniques to ensure that this is in spec, from drawings, layup boards and continuity test equipment, we ensure that our plug and play solutions are just that.

Wire harness quality goes a lot deeper than this however. At the heart of wire harness quality is the connection between the wire and the terminal. This crimp is critical to ensure safety, longevity and performance of your looms. Over crimped and wires break causing resistance and heat. Undercrimped and terminals can fall off or also heat up and can cause fire and damage.

Capability Studies

We ensure that we do capability studies for every terminal and wire combination. Our crimp settings are checked and tested prior to every job, and throughout if it is a high-quantity crimp. To add more safety to our crimps, we do not take the manufacturers’ word for it, we have our own cross-section analysis machine and software that allows us to see exactly what is happening inside a crimp and how we can ensure the perfect crimp every time. We can even provide analysis of in-house or other suppliers crimps to demonstrate where you may have unseen quality issues.

Our Cable Eye test equipment aligns with our Arcadia drawing program to ensure that manufactured product matches the drawings exactly.

We have the ability to test for continuity, voltage, diode direct and orientation, resistance, waterproofness and many other factors.

Client Focus – Codan

We’ve been working with Codan for the last 8 years, contributing to sourcing and material specifications that are suitable for the harsh environments that their products must withstand, whilst ensuring that raw material availability is not going to impact our ability to deliver to demand fluctuations.